How Different Industries in Malaysia Benefit from Industrial Robots

In recent years, Malaysia has witnessed a significant transformation across various industries with the integration of industrial robots. These technological advancements are reshaping how businesses operate, driving efficiency, and enhancing productivity.

Manufacturing Industry

The manufacturing sector in Malaysia has been one of the primary beneficiaries of industrial robots. Automation has allowed manufacturers to streamline operations, reduce labor costs, and improve product quality. With robots handling repetitive tasks, human workers can focus on more complex activities, leading to increased innovation.

Moreover, industrial robots contribute to higher production rates and precision, minimizing errors and waste. This is particularly important in sectors like electronics and automotive, where precision is crucial.

Electronics Manufacturing

In the electronics sector, robots are crucial for assembling small, delicate components. The precision offered by robots ensures that electronic products meet high-quality standards. This precision is vital for maintaining Malaysia's competitive edge in the global electronics market.

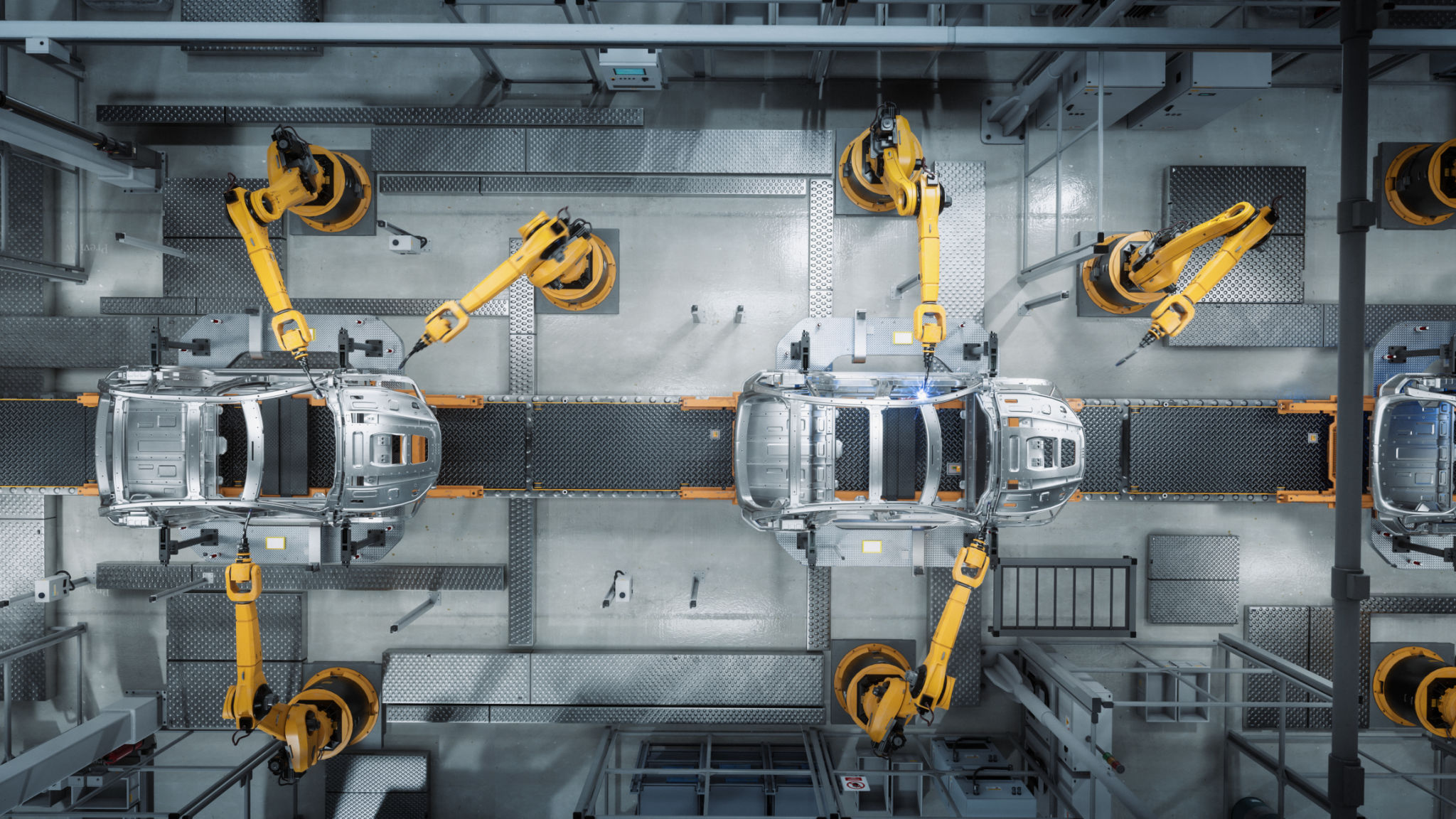

Automotive Industry

In the automotive industry, robots enhance production lines by performing tasks such as welding, painting, and assembly. These robots ensure consistency and accuracy, which are essential for producing high-quality vehicles. Additionally, robots can work tirelessly, leading to shorter production cycles and faster time-to-market for new models.

Safety and Efficiency

By taking over dangerous tasks, robots improve workplace safety. This not only protects workers but also reduces costs related to workplace injuries. The efficiency gained from robots allows companies to allocate resources more effectively.

Food and Beverage Industry

The food and beverage industry in Malaysia benefits from industrial robots through enhanced hygiene and precision. Robots are used for packaging, sorting, and quality control, ensuring products meet stringent safety standards. This automation helps in maintaining consistency and reducing food waste.

Customization and Flexibility

Robots offer the flexibility to adapt to different production lines and customize products according to consumer preferences. This adaptability is crucial in a fast-paced industry where consumer trends can change rapidly.

Conclusion

Industrial robots have become an integral part of various industries in Malaysia, driving growth and innovation. By embracing this technology, businesses can enhance productivity, improve quality, and maintain competitiveness in the global market. As technology continues to evolve, the potential for industrial robots to transform industries is bound to expand even further.