Top Trends in Robotics Automation for Malaysian Industries

Introduction to Robotics Automation in Malaysia

Robotics automation is rapidly transforming industries across the globe, and Malaysia is no exception. With the advent of advanced technologies, Malaysian industries are embracing automation to enhance productivity, reduce costs, and improve efficiency. This trend is not only reshaping manufacturing but also impacting sectors like agriculture, healthcare, and logistics.

As Malaysia aims to become a developed nation, the integration of robotics and automation is crucial. The adoption of these technologies is expected to play a pivotal role in achieving the nation's economic goals. Let's explore some of the top trends in robotics automation that are making waves in Malaysian industries.

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and ensuring workplace safety. Unlike traditional industrial robots that operate in isolation, cobots can perform tasks requiring human interaction. In Malaysia, industries such as automotive and electronics are increasingly deploying cobots to streamline operations.

The flexibility and adaptability of cobots make them ideal for small and medium-sized enterprises (SMEs) looking to automate processes without significant capital investment. By integrating cobots into their workflows, Malaysian companies can improve operational efficiency while maintaining a safe working environment.

Advancements in Artificial Intelligence

The integration of artificial intelligence (AI) with robotics is revolutionizing the way industries operate. AI-powered robots are capable of learning from data, making decisions, and performing complex tasks autonomously. In Malaysia, sectors like agriculture and healthcare are leveraging AI to optimize processes and enhance service delivery.

For instance, AI-driven robots in agriculture can monitor crop health, optimize irrigation, and even assist in harvesting. This level of automation not only boosts productivity but also ensures sustainability by minimizing resource wastage.

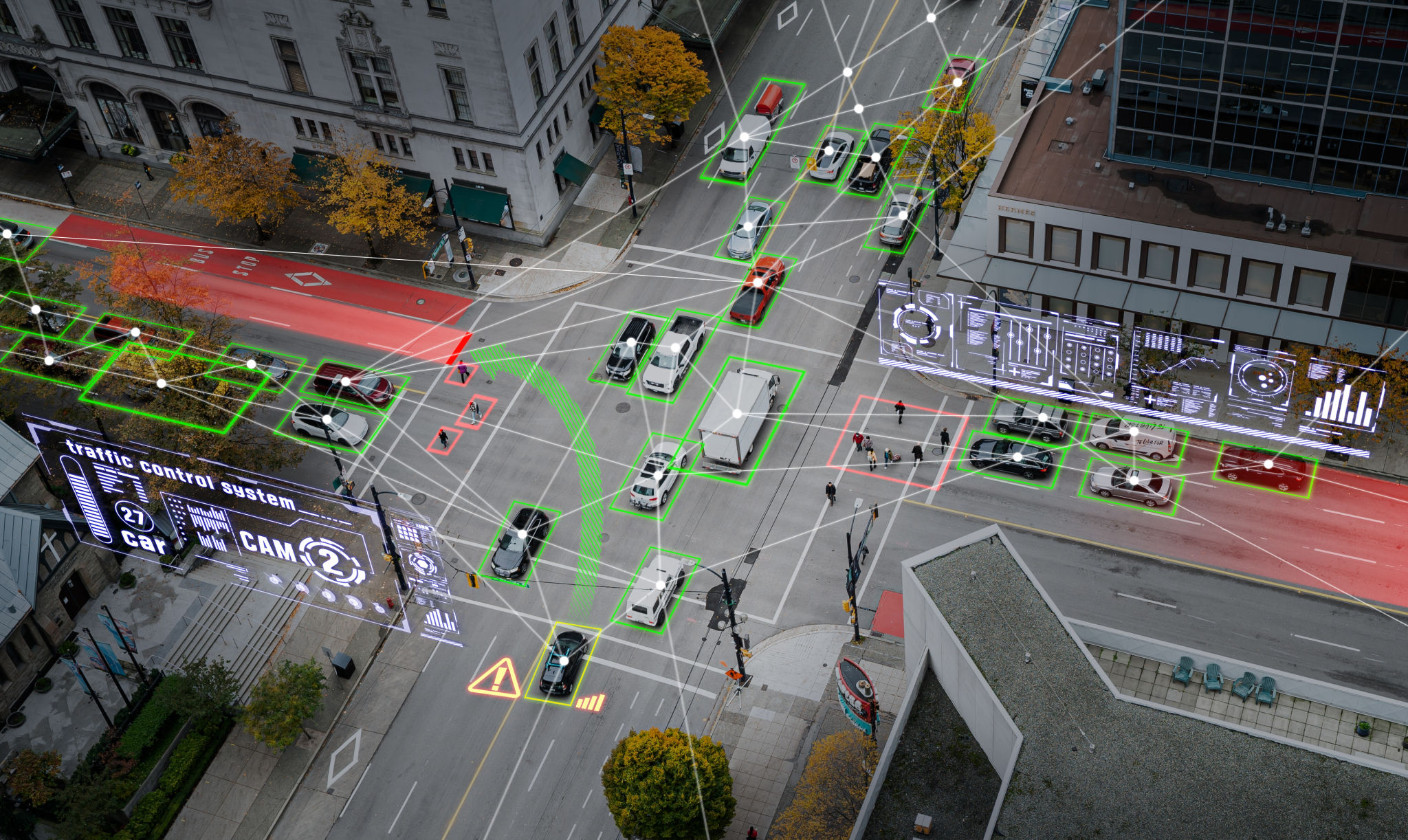

Internet of Things (IoT) and Robotics

The Internet of Things (IoT) is playing a significant role in the evolution of robotics automation. By connecting devices and systems through the internet, IoT enables real-time data collection and analysis, leading to smarter decision-making. In Malaysian industries, IoT integration with robotics facilitates predictive maintenance, reducing downtime and enhancing efficiency.

Manufacturers can leverage IoT-enabled robots to monitor equipment health and predict potential failures before they occur. This proactive approach not only saves costs but also extends the lifespan of machinery, ensuring uninterrupted production.

Logistics and Autonomous Vehicles

In the logistics sector, autonomous vehicles are becoming increasingly popular due to their ability to transport goods with minimal human intervention. Malaysia is witnessing a surge in the adoption of autonomous robots for warehouse management and delivery services. These robots can navigate complex environments, optimize routes, and manage inventory efficiently.

The use of autonomous vehicles in logistics significantly reduces operational costs while improving delivery speed and accuracy. As e-commerce continues to grow in Malaysia, the demand for automated logistics solutions is expected to rise correspondingly.

Conclusion

Robotics automation is undeniably transforming Malaysian industries by driving efficiency, innovation, and competitiveness. As these trends continue to evolve, businesses must stay informed and adapt to remain at the forefront of technological advancements. Embracing robotics not only enhances operational capabilities but also positions Malaysia as a key player in the global economy. The future of Malaysian industries looks promising as they continue to harness the power of robotics automation.